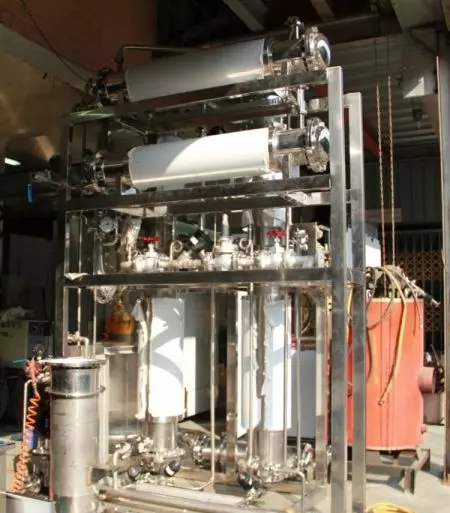

Multiple-Effect Distillation (WFI)

MS-01

Multiple-Effect Distillation (WFI) is designed to comply with the specifications of U.S. Pharmacopeia (USP) Water For Injection (WFI), and in accordance with the water quality of the supplied water source. When the temperature exceeds 80°C, the purification of water quality will be transferred in two phases.

Changing to vapor from liquid, then changing to liquid from vapor. The feed water evaporates through the heat exchanger in the evaporator, and uses its latent heat to let the evaporation process through a series of 180 degree rotations by a centrifugal cyclone baffle plate device inside the separator. Forcing the particles and water drops out by the power of flow to make the vapor that leaving the baffle plate will not contain dissolved solids and pyrogens. The particles and water drops will fall to the bottom and be heated again, condensing the purified water vapor to required distilled water by condensation transferring, using a three-way valve to discharge the unqualified purity water to ensure the water quality of distilled water, and storing in a storage tank for injection pharmaceutical use.

Features

- Water quality monitoring system.

- The product is more energy-saving than traditional single-effect type.

- Using double-tube plates design to prevent cross-contamination.

- Using double-tube plates for cooling system to prevent cross-contamination.

- Using double-tube plates for the first effect of evaporator to prevent cross-contamination.

- Each evaporator has a window to observe the internal situation of the evaporator.

- The heat-transfer tube’s expansion technology construction has good heat transfer efficiency and can be repaired and maintained.

- The internal design of the heat-transfer tube is using the temperature differences to make internal circulation, which improving the efficiency of temperature rising.

- The heat-transfer tube design of the heat exchanger improves the efficiency and achieves the energy-saving effect.

- Using the latest design for the steam-water separated baffle of evaporator to reduce endotoxins in the water effectively.

Applications

- For the Pharmaceutical.

Specification

| Model | Number of Effects | 5 Bar Steam Heating | Dimensions | |||||

|---|---|---|---|---|---|---|---|---|

| Production Capacity (Lt/hr) | Steam (kg/hr) | Cooling Water (Lt/hr) | Height (mm) | Length (mm) | Width (mm) | Weight (mm) | ||

| MS-250/4 | 4 | 250 | 85 | 280 | 2500 | 1300 | 700 | 800 |

| MS-500/4 | 4 | 510 | 150 | 500 | 2500 | 1300 | 900 | 900 |

| MS-500/5 | 5 | 510 | 130 | 300 | 2500 | 1450 | 900 | 1000 |

| MS-1000/5 | 5 | 1200 | 320 | 600 | 2900 | 1900 | 1000 | 2000 |

| MS-1000/6 | 6 | 1200 | 270 | 600 | 2900 | 2240 | 1000 | 2300 |

| MS-1500/5 | 5 | 1700 | 420 | 750 | 3200 | 3040 | 1050 | 2700 |

| MS-1500/6 | 6 | 1700 | 350 | 750 | 3200 | 3350 | 1050 | 3000 |

| MS-2000/5 | 5 | 2200 | 620 | 1000 | 3200 | 3000 | 1100 | 3300 |

| MS-2000/6 | 6 | 2200 | 550 | 1000 | 3200 | 3430 | 1100 | 3800 |

| MS-3000/6 | 6 | 3200 | 700 | 1200 | 3700 | 3900 | 1300 | 4800 |

| MS-4000/6 | 6 | 4300 | 1000 | 1400 | 3900 | 4480 | 1400 | 6800 |

※ We can accept customer specify specification.

Construction & Structure

- The equipment materials that connected to the water inlet are all using stainless steel SS316L, frosted and polished 320 ~ 400#.

- Double-tube plate design, using distillation method to treat the contaminated cooling water through the glass fiber.

- The external materials and flanges of the equipment are all using SS304.

- The pipes are passivated before actual operation.

- Double tube plate design. By using distillation method to treat contaminated cooling water through glass fiber.

- The external materials and flanges of the equipment are using SS304.

- The pipes are passivated before starting actual production.

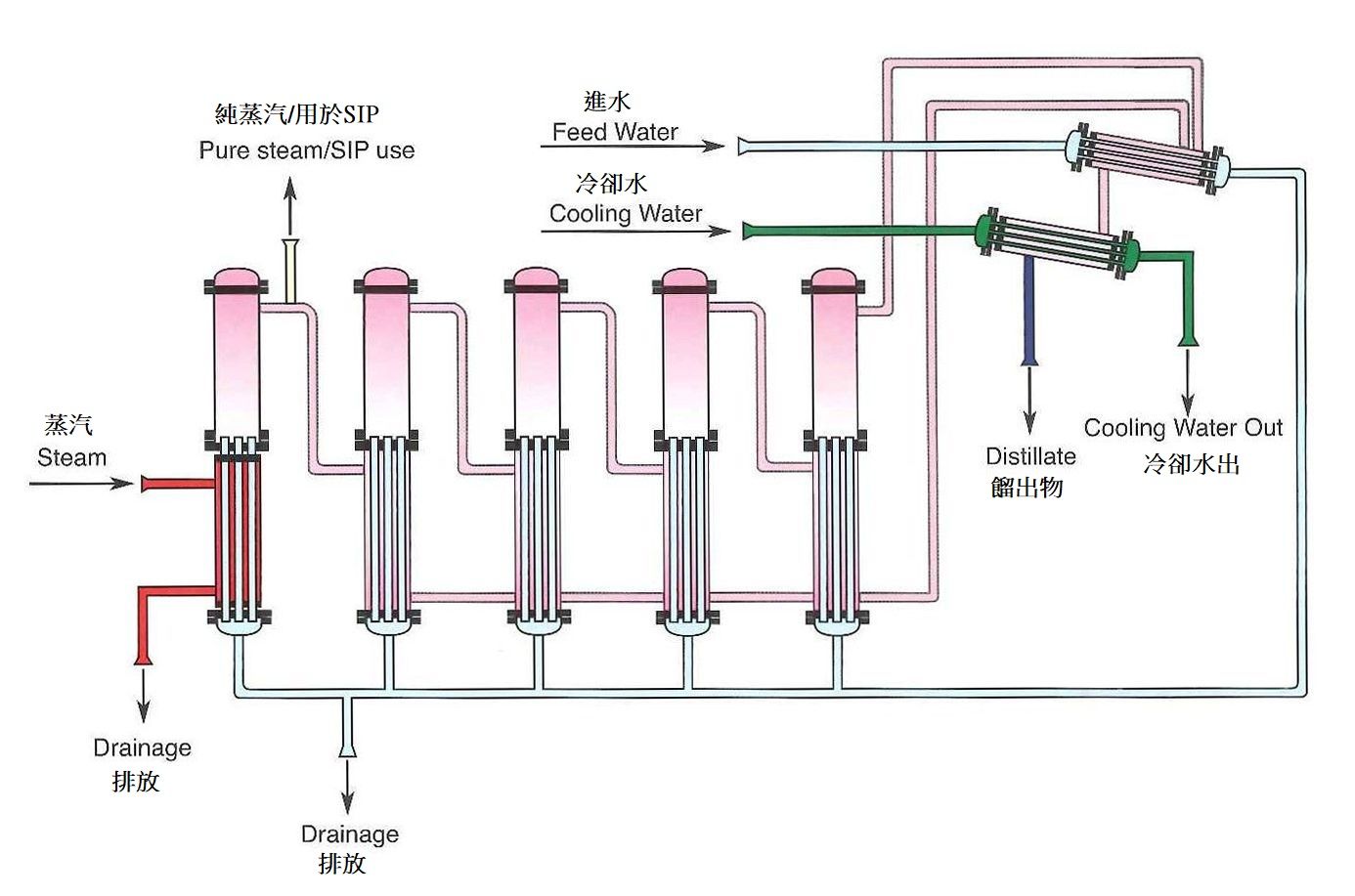

Processing Map

Process

The equipment is using the working principle of heat exchanger, the first cylinder is heated by external steam, other cylinders are heated by the first cylinder's pure steam to next cylinder. Using evaporator and condenser to force the water to proceed twice variations. Details are described as follows:

First of all, letting the feed water that inside evaporator to pass through heat exchanger, the liquid will be changed to gaseous, then using its latent heat to get into separator. There's a special mist damper and a high centrifugal force cyclone device inside the separator, the steam will pass through 180 degree continuous rotation and separate particles, drops and pyrogen when passing through the special device that mentioned above. The steam that leaves separator is sterile and does not contain solution solid and pyrogen. The particles and drops will return to the bottom of evaporator cylinder and be heated again, only the high-speed purified steam can pass through the separator and get into condenser at this stage.

After that, proceeding the second variation, the steam that inside condenser will be changed to liquid (distillate) from steam by passing through cooling exchanger, and using diverter valve to ensure the quality of distilled water. If the water quality is lower than the purity setting, then it will be discharged to drainage pipe, otherwise, it will be flown to storage tank to provide for the purpose of pharmaceutical Water For Injection (WFI).

In addition, due to the fact that it adopts multiple effect type, it will be preheated by the first condenser before injecting water to each cylinder, meanwhile, the evaporation that inside feed water latent heat piping device for each cylinder is equipped with recovery device to save the consumption of steam energy.

- Gallery

- Related Products

Pure Steam Generator

ECSG-01

Pure Steam Generators are designed and constructed to comply with the requirements of PIC/S...

DetailsPure Water System Equipment (RO+EDI)

ECPW-7000

Pure Water System Equipment adopts sanitary pipeline piping, and there's no thread lock on the main...

DetailsPure Water- Pre processing System

Quartz Sand Filtration & Activated Carbon Filtration & Resin Softener.

Details- Files Download

Multiple-Effect Distillation (WFI) - Multiple-Effect Distillation (WFI) | Taiwan-Based Pharmaceutical & Biotech Manufacturing Equipment Manufacturer | E CHUNG MACHINERY CO.

Located in Taiwan since 1975, ECMC (E CHUNG MACHINERY CO.) has been a pharmaceutical and biotech processing equipment manufacturer. Main products, including Multiple-Effect Distillation (WFI), autoclaves, WFI, water systems, pure steam generators, superheat water sterilizers, vial washing machines, tunnel sterilizers, and, in particular, hot air and steam sterilizers.

ECMC (E CHUNG) company is a professionl experienced manufacturer in the pharmaceutical sterilization industry more than 48 years so that our customers located worldwide. Sterilization machines are manufactured in line with current international standards (EU standards, US standards, GMP and GAMP, etc.).

ECMC (E CHUNG) has been providing customers high-quality cGMP pharmaceutical and biotech processing equipment, both with advanced technology and 48 years of experience, ECMC (E CHUNG) ensures each customer's demands are met.

.png?v=1c97d096)